Shot

Since 1943, our experience in the

process of manufacturing lead products has enabled us to produce

shot of the highest quality, whether for hunting or skeet shooting.

Our lead shot are manufactured using the most modern equipment,

specialized staff, the best materials and the strictest quality

control standards, allowing us to obtain a uniform product and to

ensure a strict control of the diameters, spherical form, brightness

and hardness.

Our company uses casting systems and

also pressing systems for large sizes.

The design of our packaging

guarantees a perfect conservation of the product. All wood used for

packaging complies with the NIMF-15 standard.

| Dimensions |

|

|

The diameters of our products are in conformance with

the American Standard regulation. We also manufacture other

smaller or larger sizes up to buck shot. Please, call us or

email us for other measures not included in the chart.

Shot

Size |

Diameter |

Ave. Pellet Count per Ounce (28 gr) |

|

Inches |

mm |

|

10 |

0.007 |

1.78 |

868 |

|

9 |

0.08 |

2.03 |

585 |

|

8 1/2 |

0.085 |

2.16 |

470 |

|

8 |

0.09 |

2.28 |

409 |

|

7 1/2 |

0.095 |

2.41 |

350 |

|

7 |

0.1 |

2.54 |

299 |

|

6 |

0.11 |

2.79 |

223 |

|

5 |

0.12 |

3.02 |

172 |

|

4 |

0.13 |

3.30 |

136 |

|

6 |

0.11 |

2.79 |

223 |

|

| Hardness |

|

|

According to the alloy used, we can offer different

hardness for our product. We produce pellets with hardness

that equals a content of antimony between 2% and 5%. |

| Packaging |

The pellet is packed in two ways: |

|

In cotton bags with reinforced seams and a heat sealed

plastic lining on the inside, which contain 11.33 kg (25

lb.). 80 bags per case = 908 kg (2000 lbs.).

External dimensions of the box:

50 cm Height x 56 cm Width x 96.5 cm Length |

|

In metal cylinders, straped on a wooden pallet with a

plastic bag inside. The cylinders can weight 1360 kg (3000

lbs.) or 1450kg (3197 lbs.) The external dimensions of the

cylinder are:

56 cm Diameter x 86 cm Height |

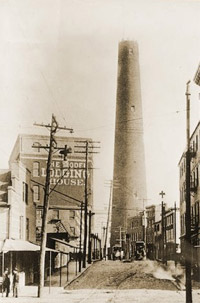

The dream that

revolutionized the manufacturing of shot

During the mid-eighteenth century, two different methods were used

to make bullets and shots depending on their size. Large shots were

melted on molds, a fairly obvious method, although very hard to work

with and that also left marks on the joints. Another method, which

was used for smaller shot, consisted of pouring melted lead through

a sieve suspended several centimeters over a barrel with water. The

size of the sieve holes determined the diameter of the shot. This

second method was not perfect either, and the results were oval

shots with the figure of teardrops with a "tail”. It was necessary

then to pass them through a machine that would eliminate the major

flaws to finally get a roughly spherical shot.

There

is a story that mentions that one night in 1782, a plumber from

Bristol, England, whose last name was Watts ended up drunk, and

unable to get home he spent the night sleeping at the base of the

steeple at Saint Mary Redcliff church. That night he dreamed that

from the top of the tower he dropped molten lead through a sieve and

this fell into a container with water. There is another version of

the dream, perhaps more in line with the fears of a married drunk

man. In this, Watts dreamed that his wife was the one who poured

molten lead at him from the church tower through the holes of a big

pan. However the idea came about, Watts and his wife decided to try

it. And they chose to do it at the church tower from the dream, so

they placed a barrel with water on the floor. The test was a success,

so after pouring molten lead it fell like raindrops and during the

fall, the air began to cool the metal cells, the water cushioned the

drop fall and solidify them. There was no more waiting. So Watts

decided to patent the process and in early 1785, he could implement

his idea. That year, Watts rented a house on Redcliff Hill, the same

street where he had a plumbing business, and he began what would

become the first "tower for shots manufacturing". Today, various

processes are used for the production of shots but there are still

some factories around the world, which currently use a tower like

the one Watts dreamed of.

There

is a story that mentions that one night in 1782, a plumber from

Bristol, England, whose last name was Watts ended up drunk, and

unable to get home he spent the night sleeping at the base of the

steeple at Saint Mary Redcliff church. That night he dreamed that

from the top of the tower he dropped molten lead through a sieve and

this fell into a container with water. There is another version of

the dream, perhaps more in line with the fears of a married drunk

man. In this, Watts dreamed that his wife was the one who poured

molten lead at him from the church tower through the holes of a big

pan. However the idea came about, Watts and his wife decided to try

it. And they chose to do it at the church tower from the dream, so

they placed a barrel with water on the floor. The test was a success,

so after pouring molten lead it fell like raindrops and during the

fall, the air began to cool the metal cells, the water cushioned the

drop fall and solidify them. There was no more waiting. So Watts

decided to patent the process and in early 1785, he could implement

his idea. That year, Watts rented a house on Redcliff Hill, the same

street where he had a plumbing business, and he began what would

become the first "tower for shots manufacturing". Today, various

processes are used for the production of shots but there are still

some factories around the world, which currently use a tower like

the one Watts dreamed of.

|

Safety Data Sheet SDS

|

|